Super Duplex Alloy UNS S32750 | F53 | 1.4410 | 2507 flanges

Negotiable Min Order Quantity Unit

- Required Quantity

-

- Place of Origin

- China

- Brand name

- Super Duplex Alloy UNS S32750 F53 1.4410 2507 flanges

- Payment Terms

- L/C,T/T,Western Union

- Production method

- Negotiable

- Shipping / Lead Time

- Negotiable / Negotiable

- Category

- Flanges

Dlh Special Material Co.,Ltd

- Verified Certificate

-

8

| Product name | Super Duplex Alloy UNS S32750 | F53 | 1.4410 | 2507 flanges | Certification | - |

|---|---|---|---|

| Category | Flanges | Ingredients | - |

| Keyword | duplex2507 flange , s32750 flange , astm a812 f53 flanges , 1.4410 flange | Unit Size | - |

| Brand name | Super Duplex Alloy UNS S32750 F53 1.4410 2507 flanges | Unit Weigh | - |

| origin | China | Stock | - |

| Supply type | - | HS code | - |

Product Information

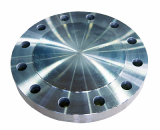

SUPER DUPLEX STEEL UNS S32750 FLANGES / A240 – UNS S32750 / EURONORM: 1.4410 – X2CrNiMoN25.7.4 / AFNOR:Z3CN25.06Az:

GENERAL PROPERTIES:-

Duplex 2507 (UNS S32750) is a super duplex stainless steel with 25% chromium, 4% molybdenum, and 7% nickel designed for demanding applications which require exceptional strength and corrosion resistance, such as chemical process, petrochemical, and seawater equipment. The steel has excellent resistance to chloride stress corrosion cracking, high thermal conductivity, and a low coefficient of thermal expansion. The high chromium, molybdenum, and nitrogen levels provide excellent resistance to pitting, crevice, and general corrosion.

APPLICATION:-

- Oil and gas industry equipment

- Offshore platforms, heat exchangers, process and service water systems, fire-fighting systems, injection and ballast water systems

- Chemical process industries, heat exchangers, vessels, and piping

- Desalination plants, high pressure RO-plant and seawater piping

- Mechanical and structural components, high strength, corrosion-resistant parts

- Power industry FGD systems, utility and industrial scrubber systems, absorber towers, ducting, and piping

COROSSION RESISTANCE:

GENERAL COROSSION:-

- high chromium and molybdenum content of 2507 makes it extremely resistant to uniform corrosion by organic acids like formic and acetic acid.

- provides excellent resistance to inorganic acids, especially those containing chlorides.

- can be used in dilute hydrochloric acid.

- Pitting need not be a risk in the zone below the borderline in this figure, but crevices must be avoided.

INTERGRANURAL COROSSION:-

- Low carbon content greatly lowers the risk of carbide precipitation at the grain boundaries during heat treatment.

- Is highly resistant to carbide-related intergranular corrosion.

STRESS COROSSION CRACKING:-

- Duplex structure of 2507 provides excellent resistance to chloride stress corrosion cracking (SCC).

- Superior to 2205 in corrosion resistance and strength.

- 2507 is especially useful in offshore oil and gas applications and in wells with either naturally high brine levels or where brine has been injected to enhance recovery.

PITTING COROSSION:-

- Different testing methods can be used to establish the pitting resistance of steels in chloride-containing solutions.

CREVICE COROSSION:-

- Highly resistant to crevice corrosion.

PROCESSING

HOT FORMING:-

2507 should be hot worked between 1875°F and 2250°F. This should be followed by a solution anneal at 1925°F minimum and a rapid air or water quench.

COLD FORMING:-

Most of the common stainless steel forming methods can be used for cold working 2507. The alloy has a higher yield strength and lower ductility than the austenitic steels so fabricators may find that higher forming forces, increased radius of bending, and increased allowance for springback are necessary. Deep drawing, stretch forming, and similar processes are more difficult to perform on 2507 than on an austenitic stainless steel. When forming requires more than 10% cold deformation, a solution anneal and quench are recommended.

HEAT TREATMENT:-

2507 should be solution annealed and quenched after either hot or cold forming. Solution annealing should be done at a minimum of 1925°F. Annealing should be followed immediately by a rapid air or water quench. To obtain maximum corrosion resistance, heat treated products should be pickled and rinsed.

WELDING:-

2507 possesses good weldability and can be joined to itself or other materials by shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), plasma arc welding (PAW), flux cored wire (FCW), or submerged arc welding (SAW). 2507/P100 filler metal is suggested when welding 2507 because it will produce the appropriate duplex weld structure.

Preheating of 2507 is not necessary except to prevent condensation on cold metal. The interpass weld temperature should not exceed 300°F or the weld integrity can be adversely affected. The root should be shielded with argon or 90% N2/10% H2 purging gas for maximum corrosion resistance. The latter provides better corrosion resistance.

CHEMICAL PROPERTIES:

Typical values (Weight %)

| C | Cr | Ni | Mo | N | Others |

|---|---|---|---|---|---|

| 0.020 | 25 | 7 | 4.0 | .27 | S=0.001 |

MECHANICAL PROPERTIES:

| Ultimate Tensile Strength, ksi | 116 min. |

|---|---|

| 0.2% Offset Yield Strength 0.2%, ksi | 80 min. |

| 0.1% Offset Yield Strength 0.2%, ksi | 91 min. |

| Elongation in 2 inches, % | 15 min. |

| Hardness Rockwell C | 32 max. |

| Impact Energy, ft.-lbs. | 74 min. |

PHYSICAL PROPERTIES:

| Density | lb/in3 | 0.28 |

|---|---|---|

| Modulus of Elasticity | psi x 106 | 29 |

| Coefficient of Thermal Expansion 68-212°F/°F |

x10-6/°F | 7.2 |

| Thermal Conductivity | Btu/h ft °F | 8.7 |

| Heat Capacity | Btu/lb/°F | 0.12 |

| Electrical Resistivity | W-in x 10-6 | 31.5 |

| ASME/ANSI B16.5 | Welding Neck Flange, Slipon Flange, Blind Flange, High Hub Blind Flange, Socket Weld Flange, Lap Joint Flange, Threaded Flange, Ring Type Joint Flange |

|---|---|

| Pressure Class | 150, 300, 400, 600, 900, 1500, 2500 |

| ASME/ANSI B16.47 | Welding Neck Flange, Blind Flange (Series A & B) |

| Pressure Class | 75, 150, 300, 400, 600, 900 |

| ASME/ANSI B 16.36 | (Orifice Flanges) Welding Neck Flange, Slipon Flange, Threaded Flange |

| Pressure Class | 300, 400, 600, 900, 1500, 2500 |

| BS 4504 SEC 3.1 | Welding Flange (111/134), Hubbed Slipon Flange (112), Hubbed Threaded Flange (113), Lapped Pipe End Flange (133), Plate Flange (101), Loose Plate Flange (102), Loose Plate with Weld-neck Flange (104), Blank Flange (105) |

| Pressure Class | PN 2.5 to PN 100 |

| Din Flanges | DIN2527, DIN2566, DIN2573, DIN2576, DIN2641, DIN2642, DIN2655, DIN2656, DIN2627, DIN2628, DIN2629, DIN2631, DIN2632, DIN2633, DIN2634, DIN2635, DIN2636, DIN2637, DIN2638, DIN2673 |

| Pressure Class | PN 6 to PN 100 |

| ANFOr NFE 29-230 | Plate Flange (01), loose Plate Flange (02, 03, 04), Blind Flange (05), Welding Neck flange (11), Hubbed Slip on Flange (12), Screwed Flange (13),Hubbed Socket Welding Flange (14), Loose Hubbed Flange (15) Integral Flange (21) |

| Pressure Class | Iso - PN 2.5 to PN 40 |

| Pr EN 1092-1 Flanges | Plate Flange (01), Loose Plate Flange (02, 04), Blind Flange (05), Welding Neck Flange (11), Hubbed Slip on flange (12), Screwed Flange (13), Integral Flange (21) |

| Pressure Class | PN 2.5 to PN 100 |

| ASME/ANSI B 16.9/MSS SP-4 | Stub End |

| Type | A, B, C |

| Metal | Grade | UNS Number |

|---|---|---|

| Austenitic / Ferritic / Austenitic / Stainless Steel | F304 / F304H / F304L * |

S30400 / S30409 / S30403 S30900 S31000 / S31009 S31600 / S31609 / S31603 S31700 / S31703 S32100 / S32109 S34700 / S34709 S31803 / S32205 S32750 S44600 |

| Ferritic / Martensitic Alloys | F1* |

K12822 K41545 / K42544 S41000 K90941 K11597 / K11572 K21590 K90901 K11564 |

| Nickel & Nickel Based Alloys | Nickel 200* Nickel 201* Alloy 400* Alloy 600* Alloy 601 Alloy 625 Alloy 800 / 800H / 800HT* Alloy 825* Alloy 904L* Alloy 20* Alloy C276* |

N02200 N02201 N04400 N06600 N06601 N06625 N08800 / N08810 / N08811 N08825 N08904 N08020 N10276 |

| Low Temperature Alloys | LF - 1* LF - 2* LF - 3* A707 L3* A694 F42 - F65* A350 LF6* |

K03009 |

| Aluminum Alloys | Alum 3003*

Alum 6061 |

A93003

A96061 |

| Copper - Nickel Alloys | 70/30 90/10 |

C71500 C70600 |

| ASTM | 304/304L/304H, 316/316L/316H, 317/317L, 321/321H, 347/347H, 316Ti, F51 |

|---|---|

| DIN | WNR 1.4541, WNR 1.4571, WNR 1.4301, WNR 1.4306, WNR 1.4307, WNR 1.4401, WNR 1.4404, WNR 1.4438, WNR 1.4462 |

| AFNOR (NF E) | BF Z 3 CN 19-09, BF Z 7 CN 18-09, BF Z 6 CNT 18-10, BF Z 3 CND 17-11-02, BF Z 7 CND 17-11-02, BF Z 6 CNDT 17-12, BF Z 6 CNDNb 18-12 |

B2B Trade

| Price (FOB) | Negotiable | transportation | - |

|---|---|---|---|

| MOQ | Negotiable | Leadtime | Negotiable |

| Payment Options | L/C,T/T,Western Union | Shipping time | Negotiable |

- President

- Alex Lane

- Address

- No.308 Jinxuan Road, Jianghai Economic Park Area

- Product Category

- Flanges

- Year Established

- 1969

- Company introduction

-

Now,pick up your phone to call us (86-17306930653) or send an email to us(dlhsm@foxmail.com).

Welcome to Dlh Special Material Co.,Ltd,looking for special metal products? Is there a brand or alloy that you cannot find? Ask us.

We are a high and new technology enterprise specializing in research, developing and manufacturing of various special alloys and hard-to-find metal materials, such as duplex stainless steel,hastelloy,incoloy,inconel,invar,monel,nickel alloys,cobalt alloys,copper alloys,titanium alloys,etc.used for the difficult jobs in engineering. These alloys are highly engineered to offer a superior combination of heat resistance, high-temperature corrosion resistance, toughness and strength and are used in the world's most technically demanding industries and applications.

We are active in the special metal market many years and therefore have extensive partnerships with reputable mills,well-connected with these mills, we can supply almost all types of products you need and can get it fast including plate/sheet/strip,pipe/tube,round/Hex/Flat bar,welding wire/rod,pipe fittings,flanges,forgings,fasteners,etc.

We can meet most ASME,ASTM,AMS,and military specifications and can cross-reference to most international standards,including full EN10204 3.1 certificate.

Our advantages below help us establish long-term cooperation with customers throughout the world.

1.A Single Source,One-stop Service.

2.Small orders accepted.

3.Inventory a lot of plates,bars,wire,etc.

4.Custom made accepted.

5.Quick reply,fast shipment.

6.Strong Technical Support.

7. Professional Sales Team.

8.Provide solution to hard-to-find materials.

The DLH Team is looking forward to handle all your inquiries and questions.

Now,pick up your phone to call us (86-17306930653) or send an email to us(dlhsm@foxmail.com).

- Main Product

China

China